H2 rear end awaiting the custom made, over-sized stainless steel drive shaft.

|  Hummer H2 rear end fitted with 3.42:1 gearing and a Detroit locker.

|

Much of this intercooler piping is useless. Red Star Performance strikes again.

| The heart of the intercooler system.

|

Measuring for the intercooler piping.

| The water-to-air intercooler's heat exchanger will have to go in front of the engine radiator and A/C heat exchanger.

|

New motor awaiting the heads.

| These ported and polished heads flow better than the 2008 Z06 Corvette heads.

|

Coolant overflow bottle had to be relocated.

|  Battery had to be relocated.

|

here you can see the ZF transmission, modified cross member and the H2 rear end.

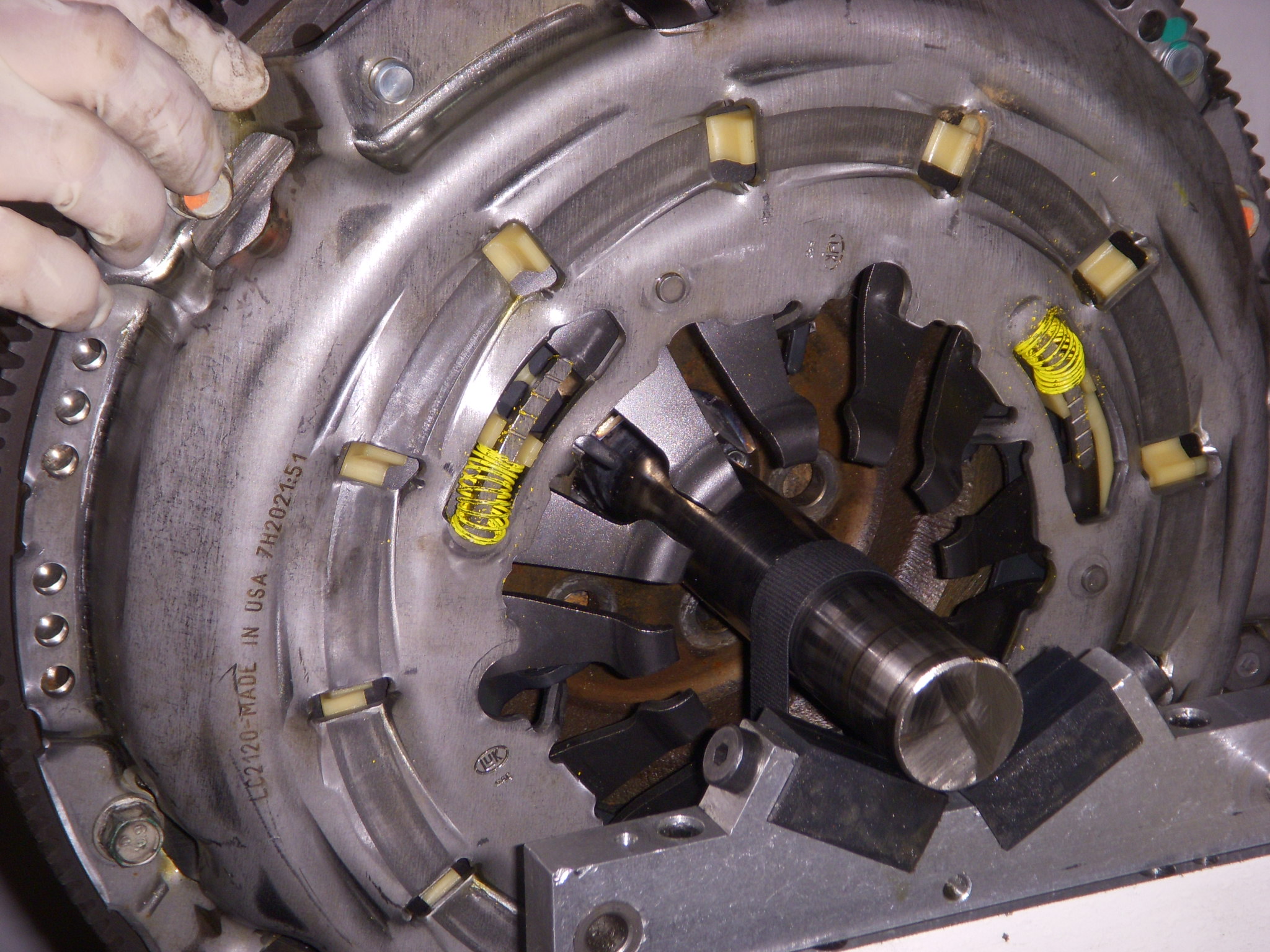

|  This clutch is absolutely MASSIVE.

|

New carpet and a new shifter location.

|  This glow-in-the-dark scorpion shifter knob came from wiseguycustoms.com. |

8-lug 20x10 Jesse James Lawless wheels wrapped in Toyo Proxes ST 2's...305/50/20.

|  Huge Hummer H2 8-lug set up.

|

Twin GT3582R turbos from Garrett.

|  cross members had to be cut to make room for that ZF transmission.

|

titanium valve spring retainers offer a little more durability.

|  stainless steel turbo piping and polished components.

|

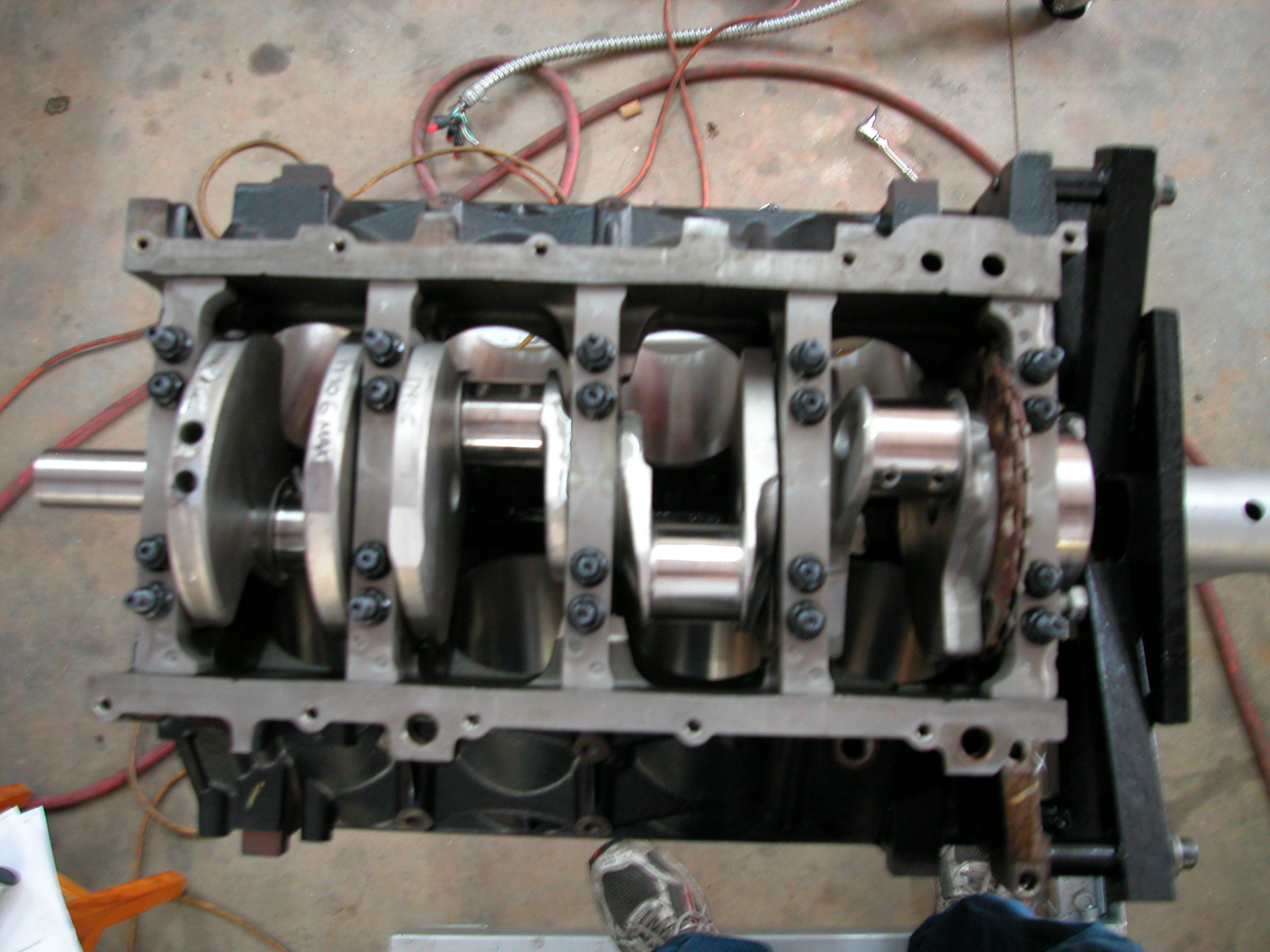

4-bolt main 6.0L LS2 block bored to 6.7L and fitted with Mahle pistons, rods and crank shaft from Eagle Performance.

|  ZF S6-650 6 speed manual transmission. Capable of towing 26,000 pounds. The floor and cross members had to be cut to make it fit.

|

Above, you can see the water-to-air radiator with fan mounted. This will all fit tucked neatly behind the stock grill and won't even be seen.

On the right, the airbox portion of the intercooler system tucks neatly away and will be protected by the truck's frame. |

The air box and heat exchanger are firmly mounted. The air box sits between the frame rails and the heat exchanger mounts to the hood-latch support.

Yokoham Geolander A/T-S tires on 16" steel wheels from a 3/4 ton Chevy will get me around in the snow this winter.

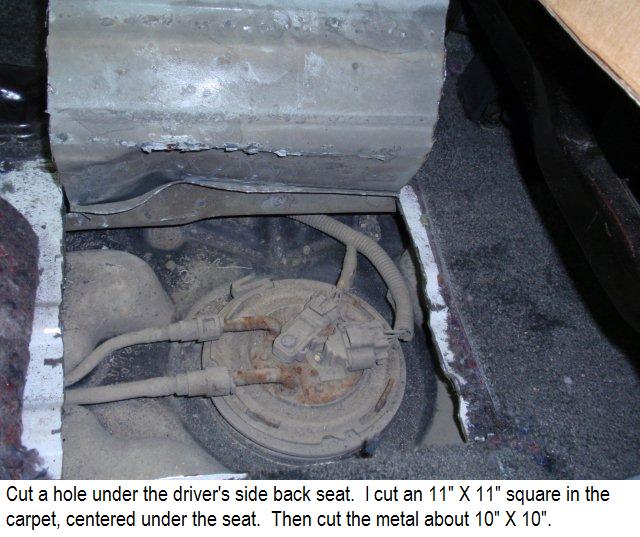

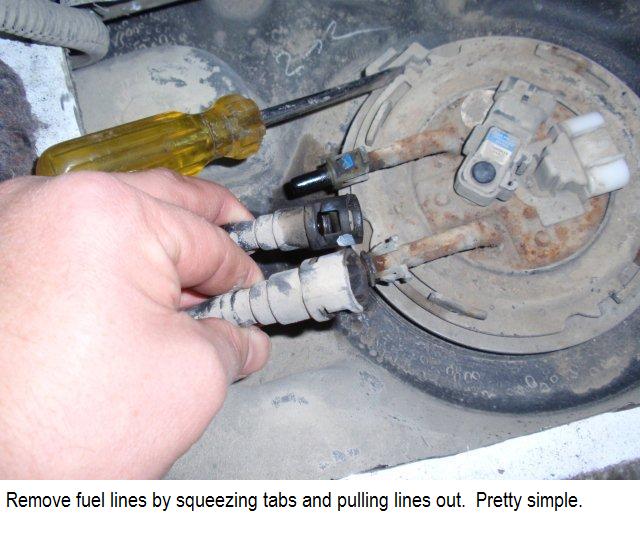

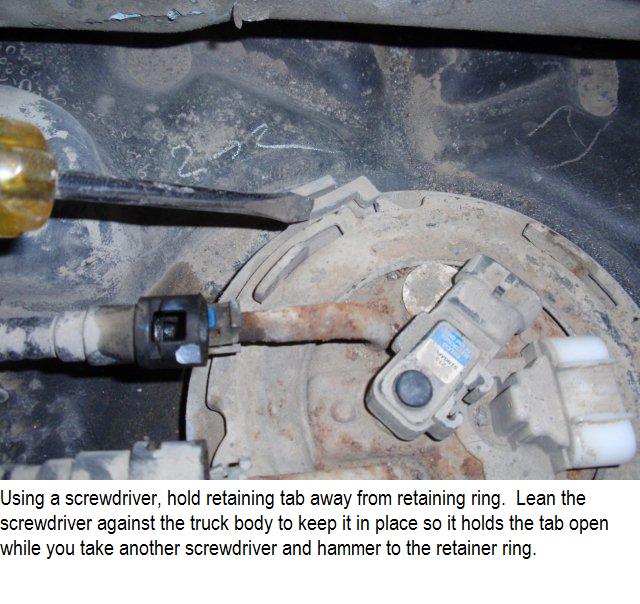

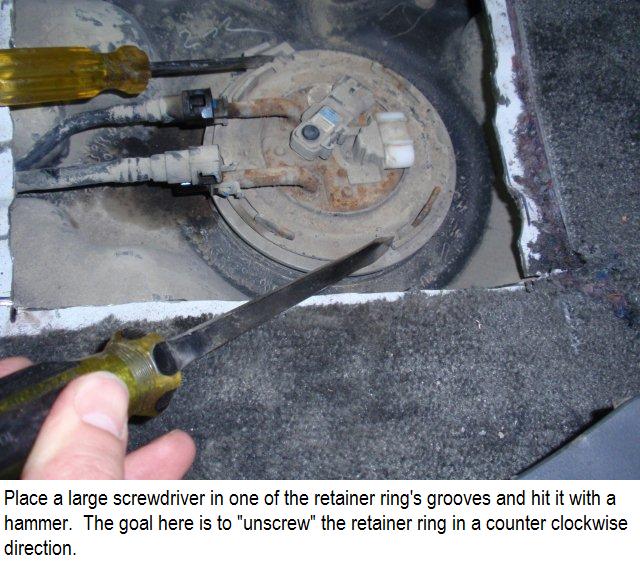

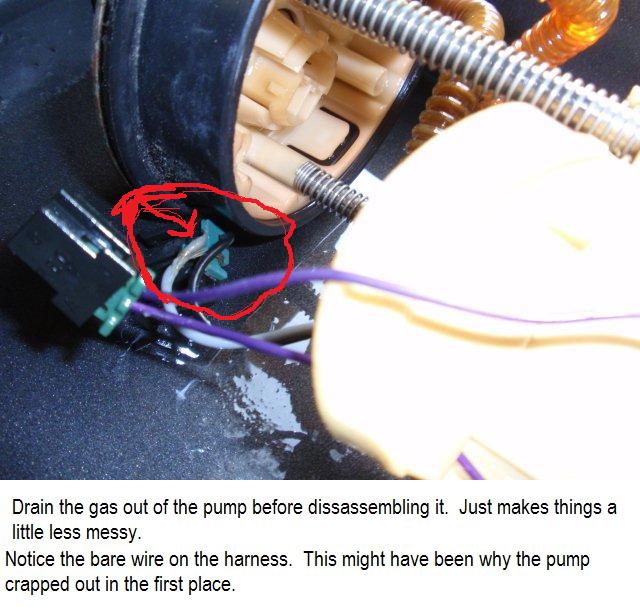

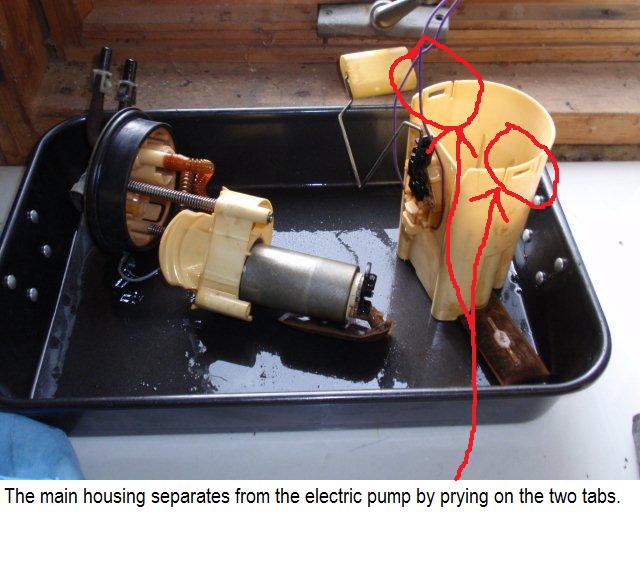

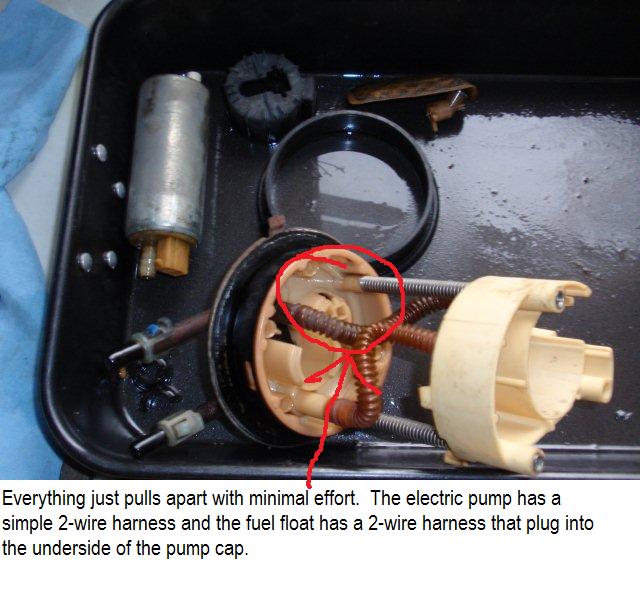

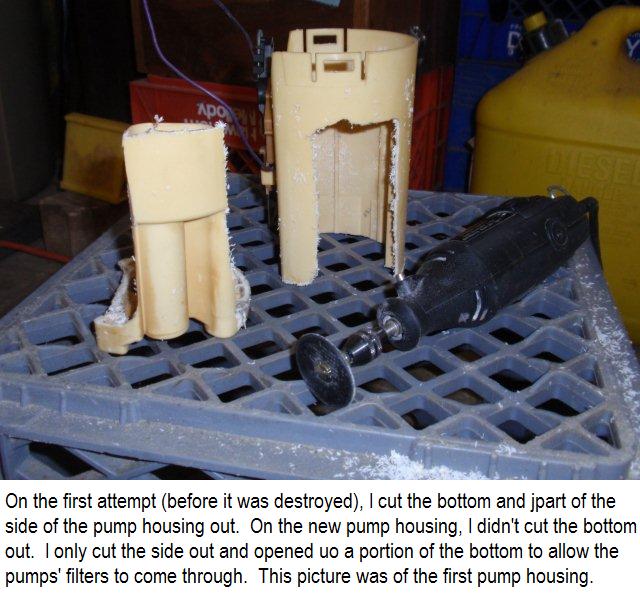

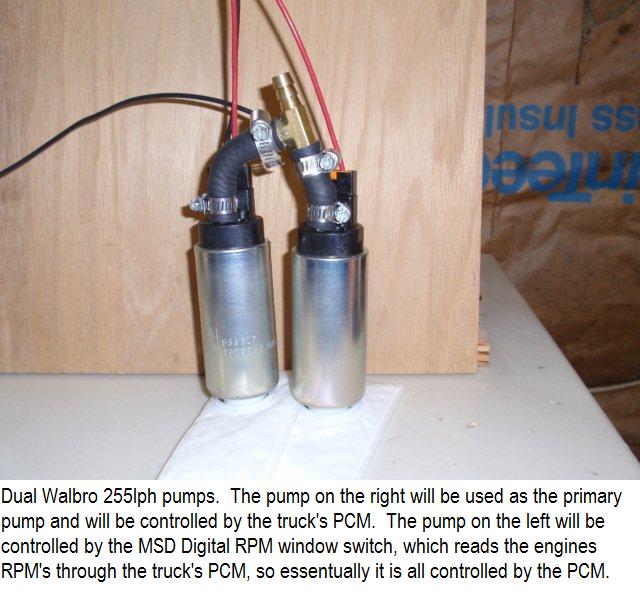

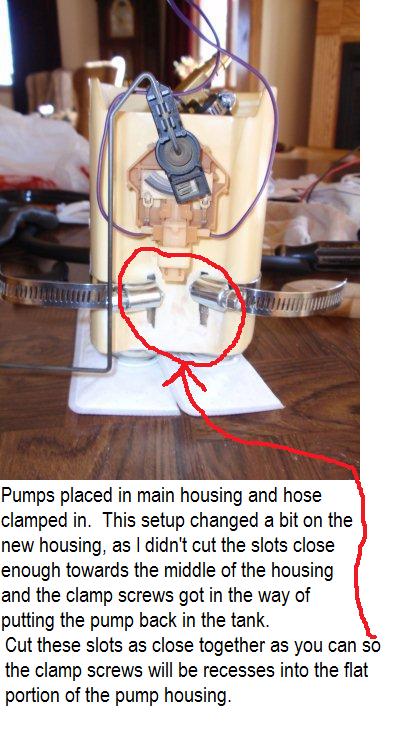

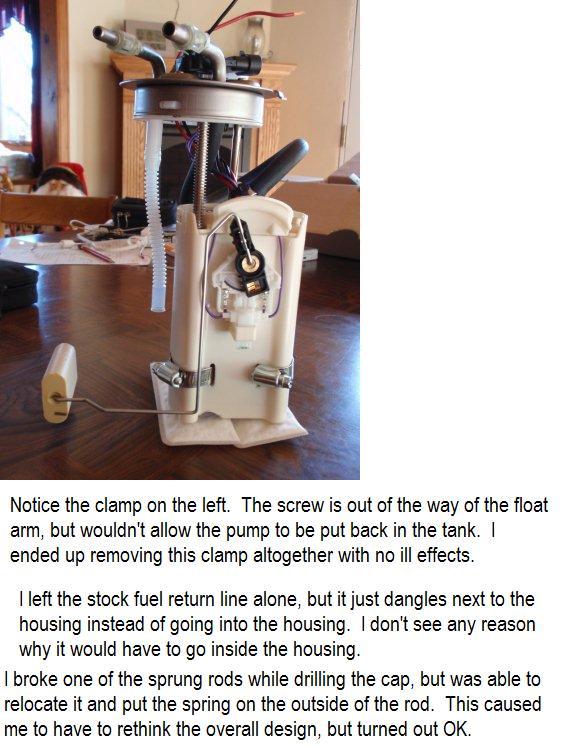

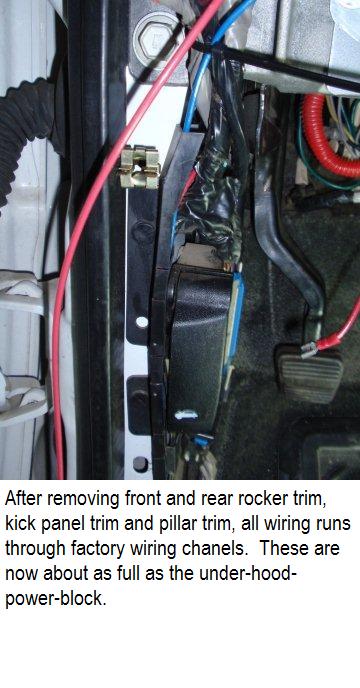

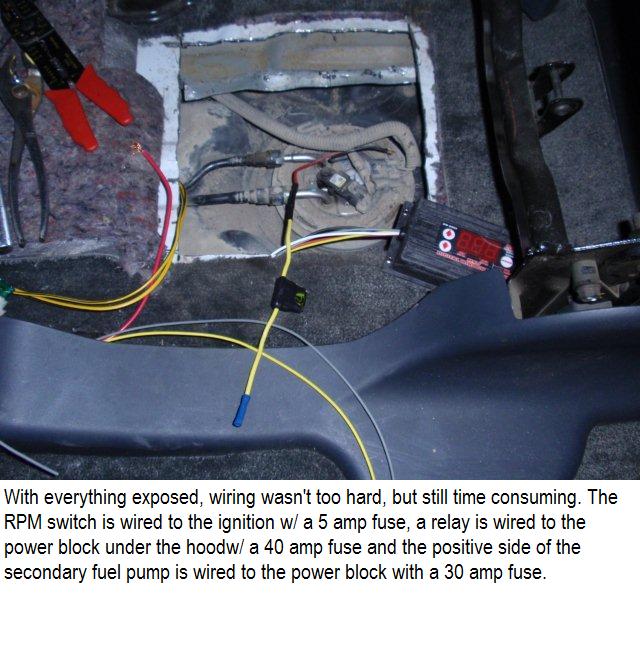

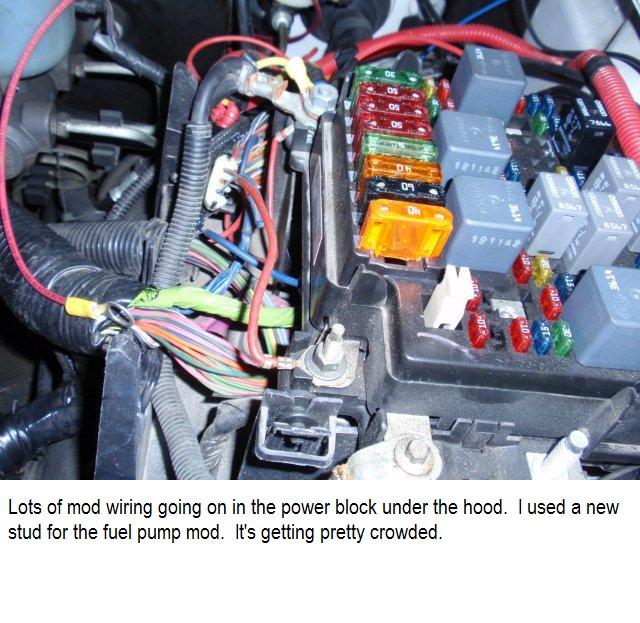

Modifying the fuel pump. The stock pump can't handle the fuel flow necessary to quench the motors thirst for fuel. Two Walbro 255lph pumps replace the stock pump.

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

| Climbing in and out of the engine bay to work on the engine and retrieve various tools is hard on the body. I must have climbed over the radiator support and onto the lower cross member 100 times a day. |

There are a lot of wires and sensors an a modern LS engine. If you get halfway through a rebuild or repair and realize you left a sensor out, you have to take it all apart again and get new gaskets, because they can't be re-used once bolts are torqued down. |  |

| The GT 2-1 cam that Red Star Performance used was lethargic, to say the least. This one really brings the motor to life. What a difference! Here's the new cam going in. This was probably the easiest part of the cam swap project...until a valve lifter dropped into the motor and I had to tear it down to replace the lifter. Not only was it very time consuming, but gaskets are expensive. |

It feels good to keep things organized. That way, if it takes longer than expected to get it back together, you can remember where the parts go. |  |